Summary: Fail Safe or Fail Lucky

The drilling industry, despite its significant advancements, continues to report dropped objects as one of the leading causes of potential incidents. This persistent issue has led to the development of various preventive measures, including routine inspections and robust securing methods. However, when these preventive measures fail, the industry relies on mitigating measures to ensure the safety of personnel. The critical question that arises when a dropped object incident occurs is whether we had anticipated this potential outcome and implemented measures to prevent harm, or whether we were merely fortunate to avoid disaster. This distinction between “failing safely” and “failing lucky” was the central theme of an industry panel discussion held on 23 June 2022.

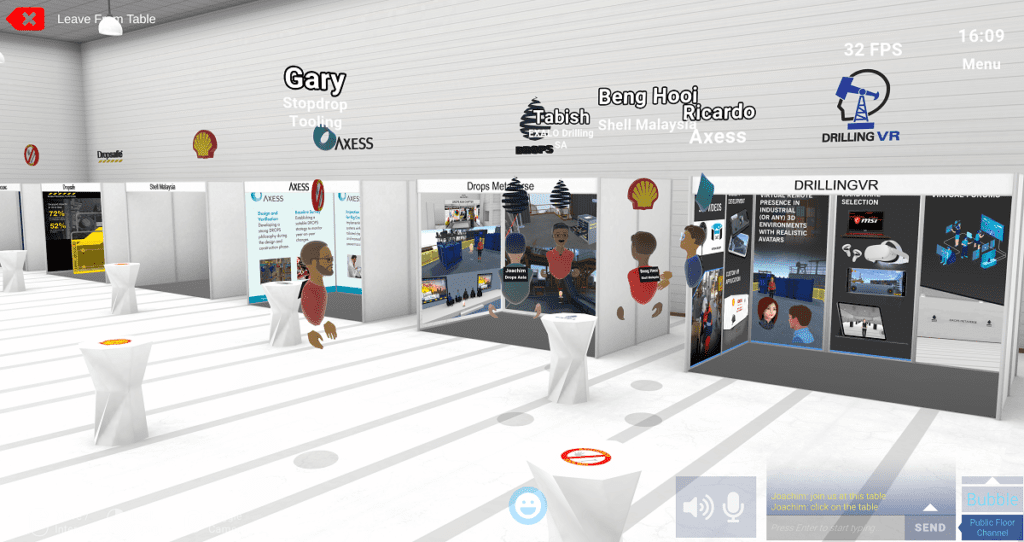

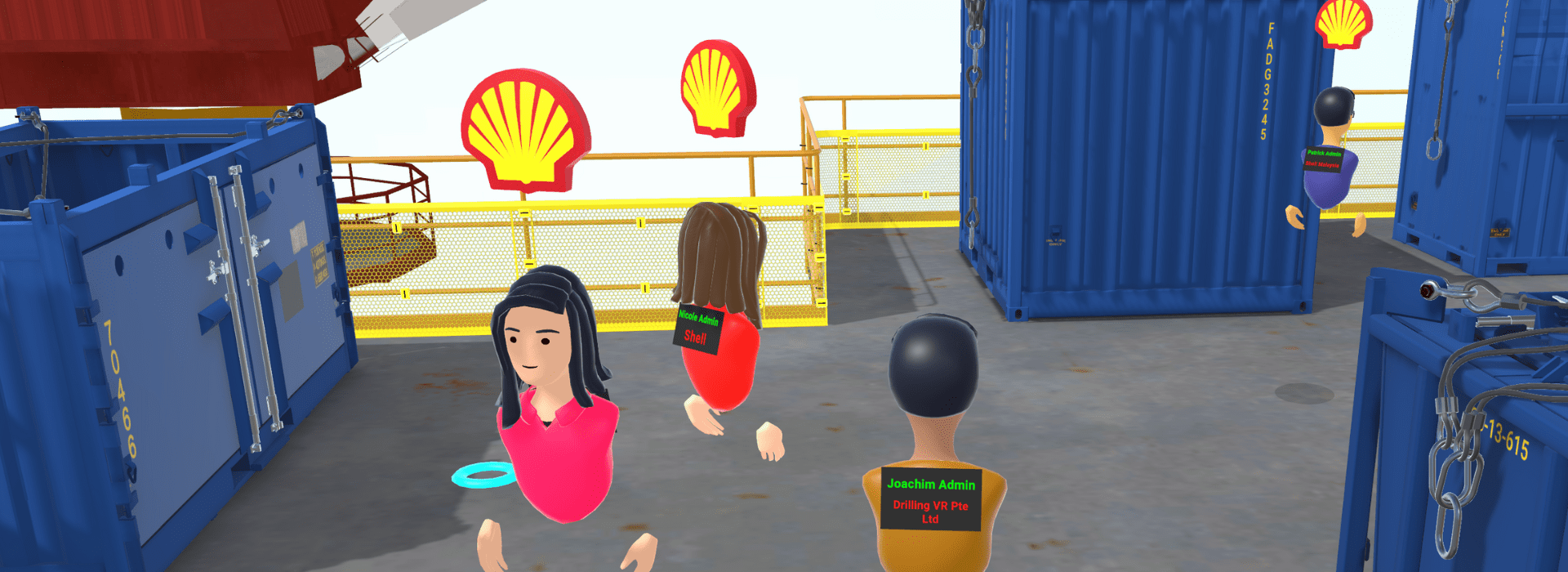

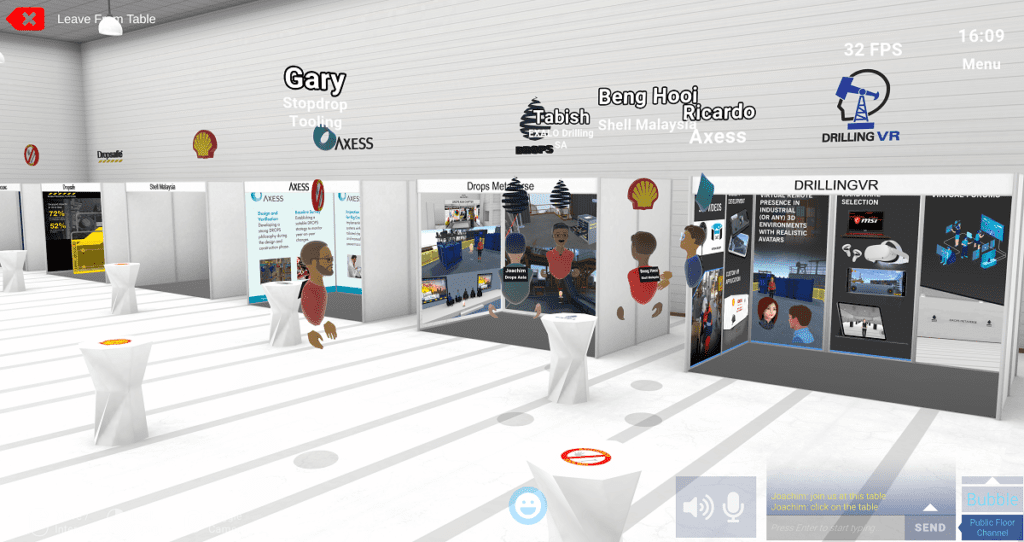

Webinar participant

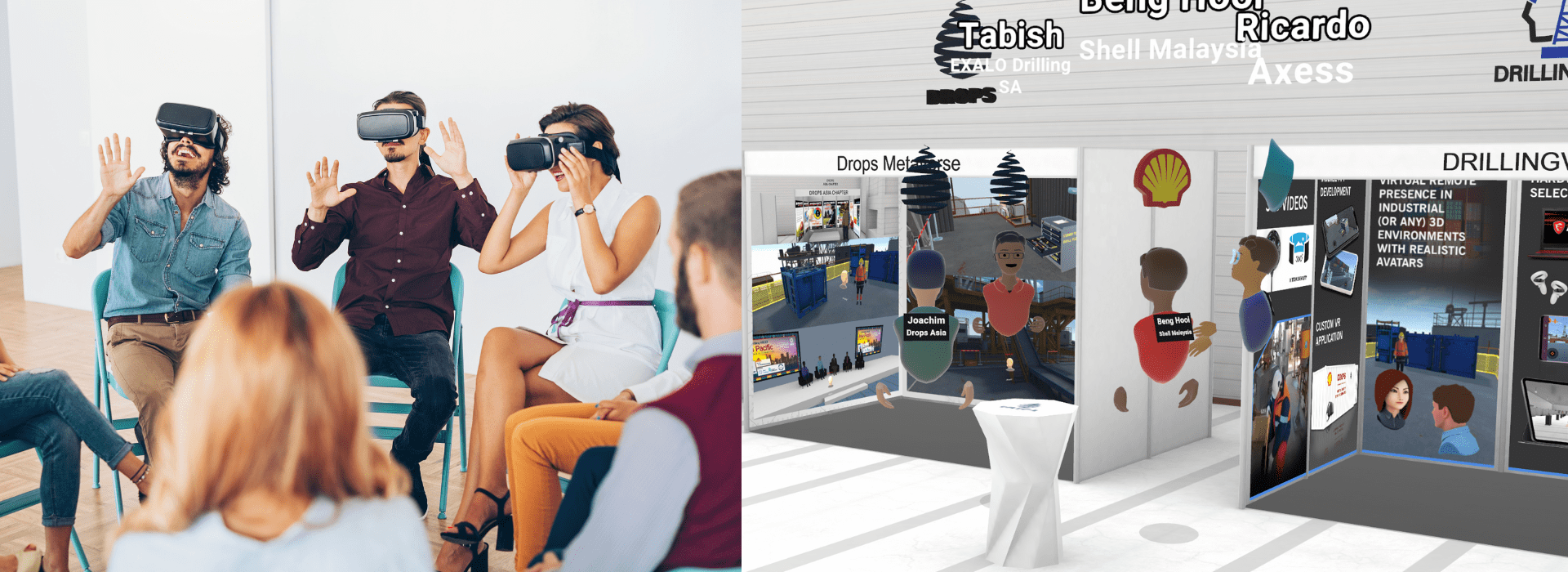

The webinar, titled “Fail Safe or Fail Lucky,” brought together industry experts Shi Beng Hooi from Shell Malaysia, David Jamieson from Bowtie Master, William Lai from Baker Hughes, and Joachim van der Meulen from DROPS Asia. The discussion was sponsored by Axess Group, Dropsafe, Stopdrop Tooling, GreenPin, and Shell Malaysia, all of which are key players in the industry committed to enhancing safety standards.

Shi Beng Hooi, representing Shell Malaysia, highlighted the company’s holistic approach to dropped objects prevention. He explained that Shell invests heavily in training and awareness programs to ensure that its workforce understands the risks and knows how to mitigate them. The company also has robust procedures and standards in place and conducts regular inspections and audits to ensure compliance.

David Jamieson, representing Bowtie Master, shared insights on the application of the bowtie risk management model in preventing dropped objects. Bowtie Master is a company that specializes in providing risk management solutions and training. David emphasized the importance of understanding and managing both the preventive and mitigating measures in the bowtie model to effectively manage the risk of dropped objects.

William Lai from Baker Hughes discussed the company’s comprehensive approach to dropped objects prevention. Baker Hughes focuses on design and engineering controls to eliminate or mitigate the risk of dropped objects. They also invest in training and competency development to ensure that their workforce is equipped with the knowledge and skills to work safely.

Joachim van der Meulen from DROPS Asia moderated the discussion, emphasizing the importance of creating a culture where safety is a core value and everyone feels empowered to speak up and take action to prevent dropped objects.

In conclusion, the “Fail Safe or Fail Lucky” webinar provided valuable insights into the challenges and strategies associated with dropped objects prevention in the drilling industry. The panelists agreed that while technical solutions are crucial, creating a culture of safety and personal responsibility is equally important. The discussion underscored the need for continuous learning, collaboration, and innovation in the industry’s ongoing efforts to enhance safety and prevent dropped objects incidents.

The presentation starts at 4m03s

Sponsors

The webinar Fail Safe or Fail Lucky was kindly sponsored by Axess Group, Dropsafe, Stopdrop Tooling, GreenPin and Shell Malaysia.

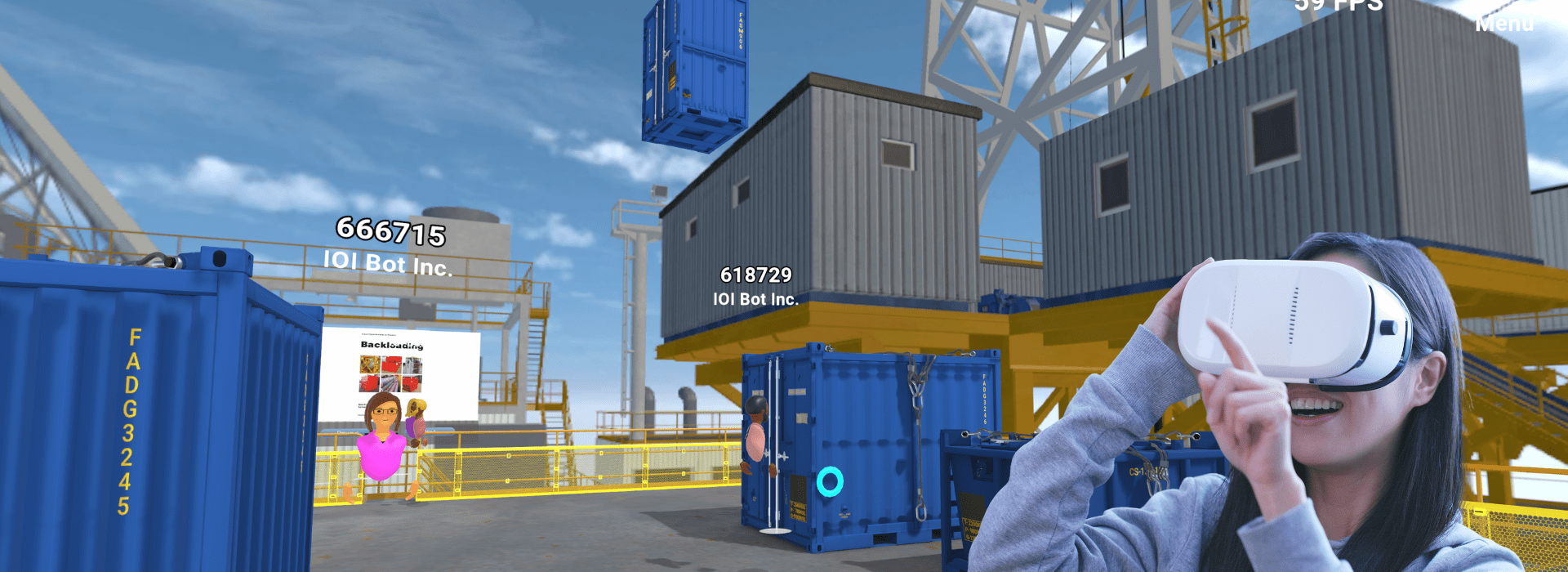

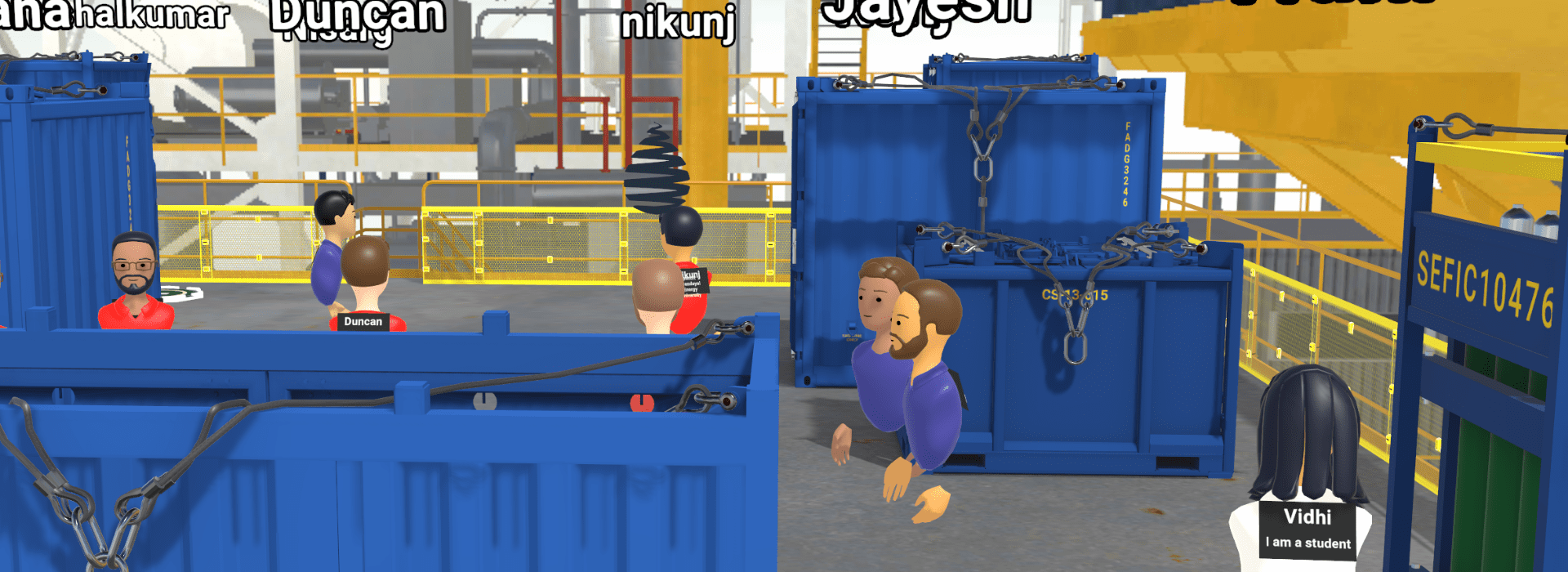

Following the webinar, participants joined the DROPS Metaverse for a virtual networking reception. To try it out for yourself, download the app for the Meta Quest (Virtual Reality), Windows or Mac here.